Mining, oil and gas

Futureproof with IoT

The mining, oil and gas industry is an economic powerhouse. According to McKinsey, within the next five years, this industry is set to generate an estimated US$930B. Through utilising and leveraging IoT solutions, which have a predicted economic impact of US$3.9T – US$11T economic impact over the same time span, this industry will strengthen its stance as a formidable economic player. By adopting IoT, this industry can not only optimise its processes and equipment but provide a safer and healthier work environment for its employees.

The solutions below can be used by our eco-system partners as a white labelled solution. Visit our Partner Program page to learn more.

Minimise downtime and improve productivity preventing emergency shutdowns

Environment monitoring to improve safety and sustainability

Manage inventory and key assets with IoT technology

Set your own metrics for real-time alerts in the palm of your hand

How IoT can help?

Our sensors can monitor and create alerting features if emergency spills happen or if there are emergency shutdowns because of spillage. This will exponentially increase the speed at which these issues can be addressed and fixed/clean-up. This means non-productive downtime (NPD) is reduced, saving the company billions in dollars and reduce damage to the surrounding environment and ecosystems.

Sensors placed on drilling equipment means that alerting features can be set to notify you if there are any drilling issues. This will send the alert to the relevant staff if there are any potential drilling errors.

Monitor remote locations

Remote monitoring of equipment and operations. With our sensors, we can provide insights and analytics based on historical data and based on this, are able to predict breakdowns and schedule preventative maintenance saving in time, money, and the manpower it takes to do these manual maintenance checks. Through the remote monitoring of operations, staff are informed and well equipped to handle any situation they may arise because of data they receive through this

Air quality monitoring and detection of hazardous air Particles

Monitor air particles such as crystalline silica dust, and automatically alerts control rooms of any abnormalities in the air.

Hazardous chemicals detection, monitoring, and alerts

Monitors and detects components such as carbon monoxide, nitrogen oxides, black carbon (above and underground) and alert control rooms of any abnormalities.

Gas monitoring

Fixed and portable gas monitors detect the presence of toxic, asphyxiant and explosive gases such as methane, hydrogen, sulfide and oxygen deficiency/enrichment.

Safeguard sustainability

Monitoring of the environment to increase staff safety. Our sensors can provide monitoring of the surrounding environment and takes into account the air quality and temperature, while also monitoring for and detecting any leakages. An alert notification will be sent if leakage occurs so that staff can evacuate before toxic levels are reached, increasing the safety and health of all staff. Environmental monitoring can also help to lower the environmental footprint generated by oil and drilling operations.

Carbon Footprint monitoring and reporting

Monitors the air quality and greenhouse gases such as carbon dioxide, methane, ozone, and nitrous oxide. Data collected assists to make educated decisions to mitigate carbon emissions.

Vibration monitoring and alerting

Monitors vibration performance in real time and triggers immediate alerts to prevent regulatory thresholds from being breached.

Ventilation units monitoring and alerts

Monitors the condition of air flow through ventilation units. Alerts are sent to authorised personnel when units are faulty or inactive.

Monitors high noise level environments

Monitors noise levels from activities such as boring, drilling, digging and loud machinery vehicles and vibration performance in real time.

Object identification and differentiation

AI capabilities to accurately identify and differentiate between people demographics, vehicle types, machinery assets, and provide real time location information.

Fridge/Freezer temperature monitoring

Monitor the temperature of mining chillers and compressed air dryers to avoid any equipment from overheating.

Waste management

Monitors and differentiate the type and quantity of waste generated onsite, proportions of waste, recycling vs landfill waste, and sources of waste.

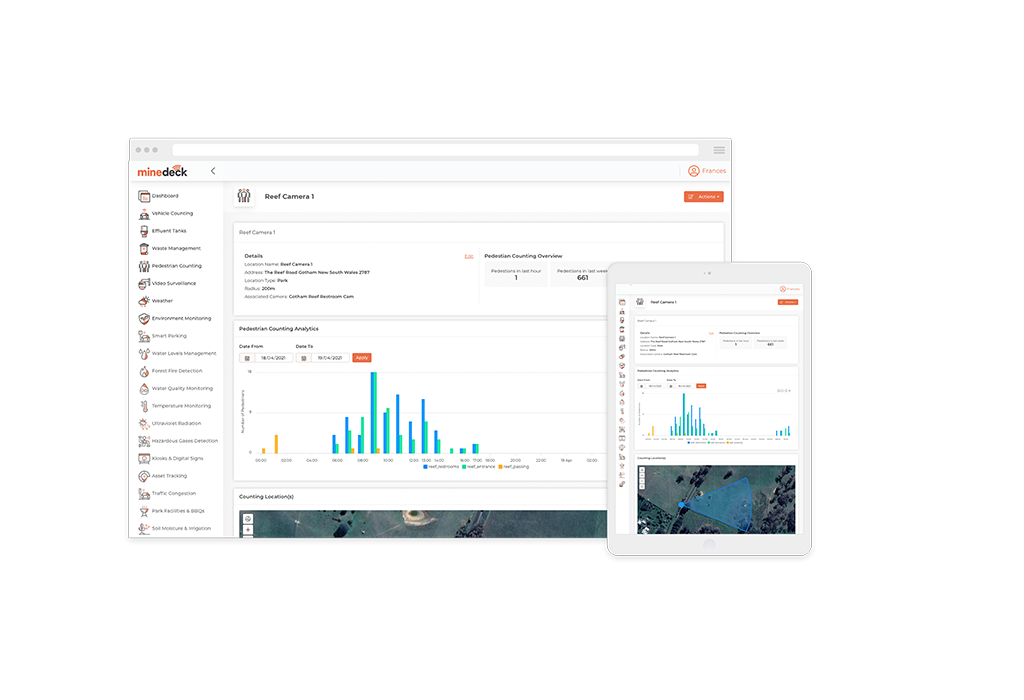

People and vehicle counting in mining areas

Our sensors can monitor the number of people in an area in real-time. This will help determine the exact number of people if evacuation is needed due to an unexpected incident, resulting in reducing the number of fatalities. By using IoT-enabled safety measures, oil and gas companies can provide their workers with a safe working environment. The companies can also benefit from lower insurance and corporate liability.

Count and keep track of vehicles, machinery

and assets entering underground and above

ground.

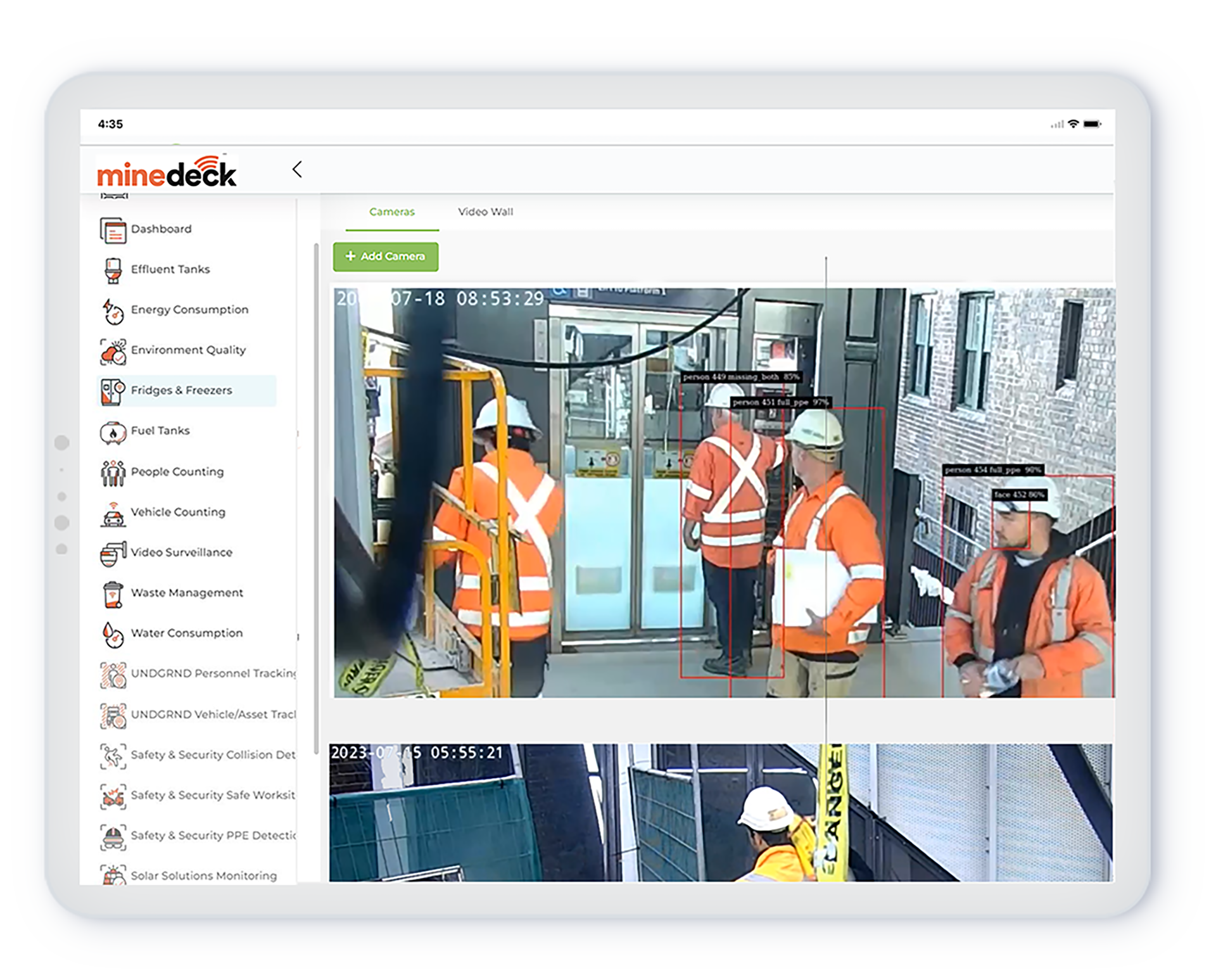

Smart Video Surveillance

Accurately monitor and detect for property intrusion, theft and provides real time location information.

Theft detection with real time notifications

Monitor people and vehicles who enter and leave worksite, with real time notifications being directly sent to security personnel on

duty via their phones or devices.

Secure access control

Only give access to specific areas on site to certain people at certain times.

Improve visibility and controls

Inventory supply tracking and monitoring, including supply chain management. If an item is missing, an IoT system can be used to track shipments with the exact location of each oil and gas asset. IoT helps in efficient planning and scheduling in the supply-chain process. Sensors can be used to detect oil incoming and the location of where these are stored. This data can aid in operation decisions and provides transparency in the supply chain management.

Environment Monitoring

Monitor and record various environmental readings on site such as noise, vibration, temperature, air quality and gas.

Energy Consumption

Monitors and provides a report consolidating the worksites’ overall electricity and water consumption on per day, week, month, and year.

Solar Solutions Monitoring

Monitor solar energy and other renewable energy sources used to generate electricity, run air conditioning and lighting, and charge battery banks.

Weather Monitoring

Monitor the site’s temperature, humidity, rainfall, and water flow pressure. Use data to make educated decisions around boring and mining the field.

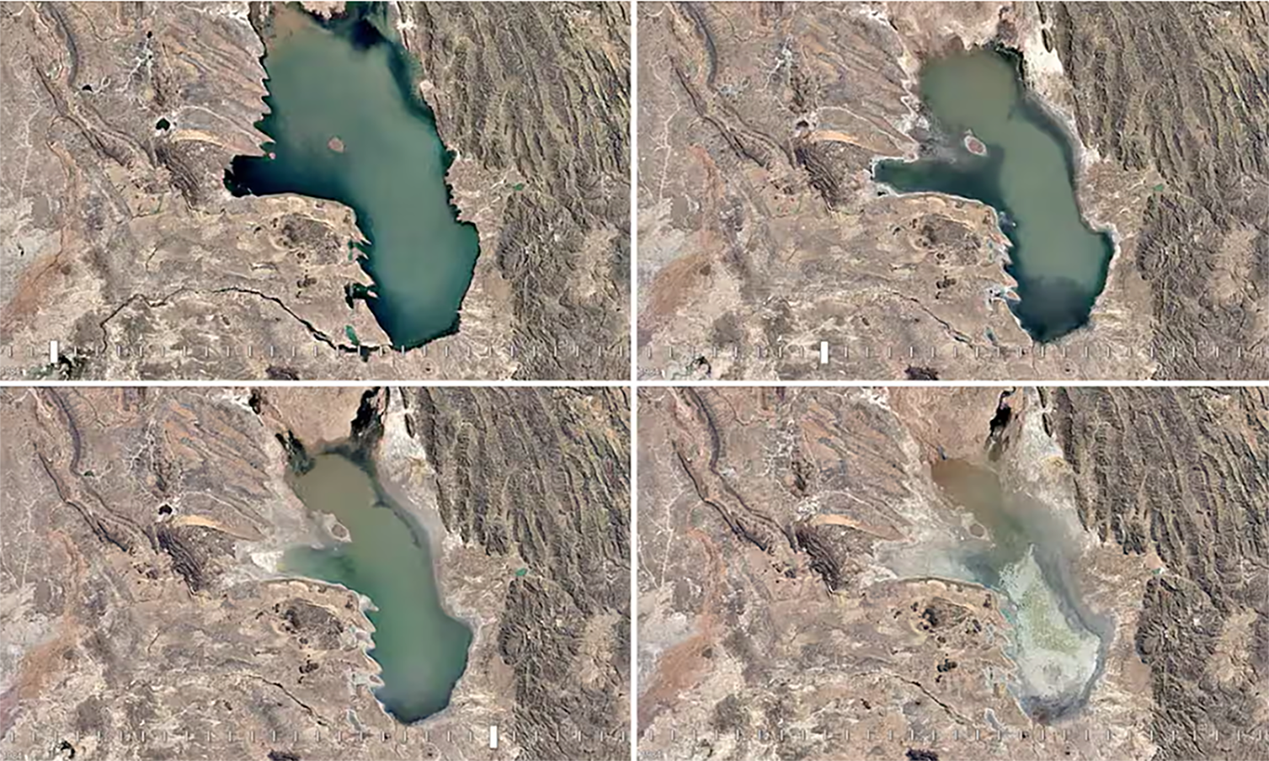

Workplace Project Timelapse and Digital Twin

Periodic satellite imagery of projects and onsite cameras will allow companies to create a historical progression timeline of the mining.

Our Digital Twin solution will also allow for companies to virtually gain visibility over the mining site (above and underground) and collect data with environmental simulations

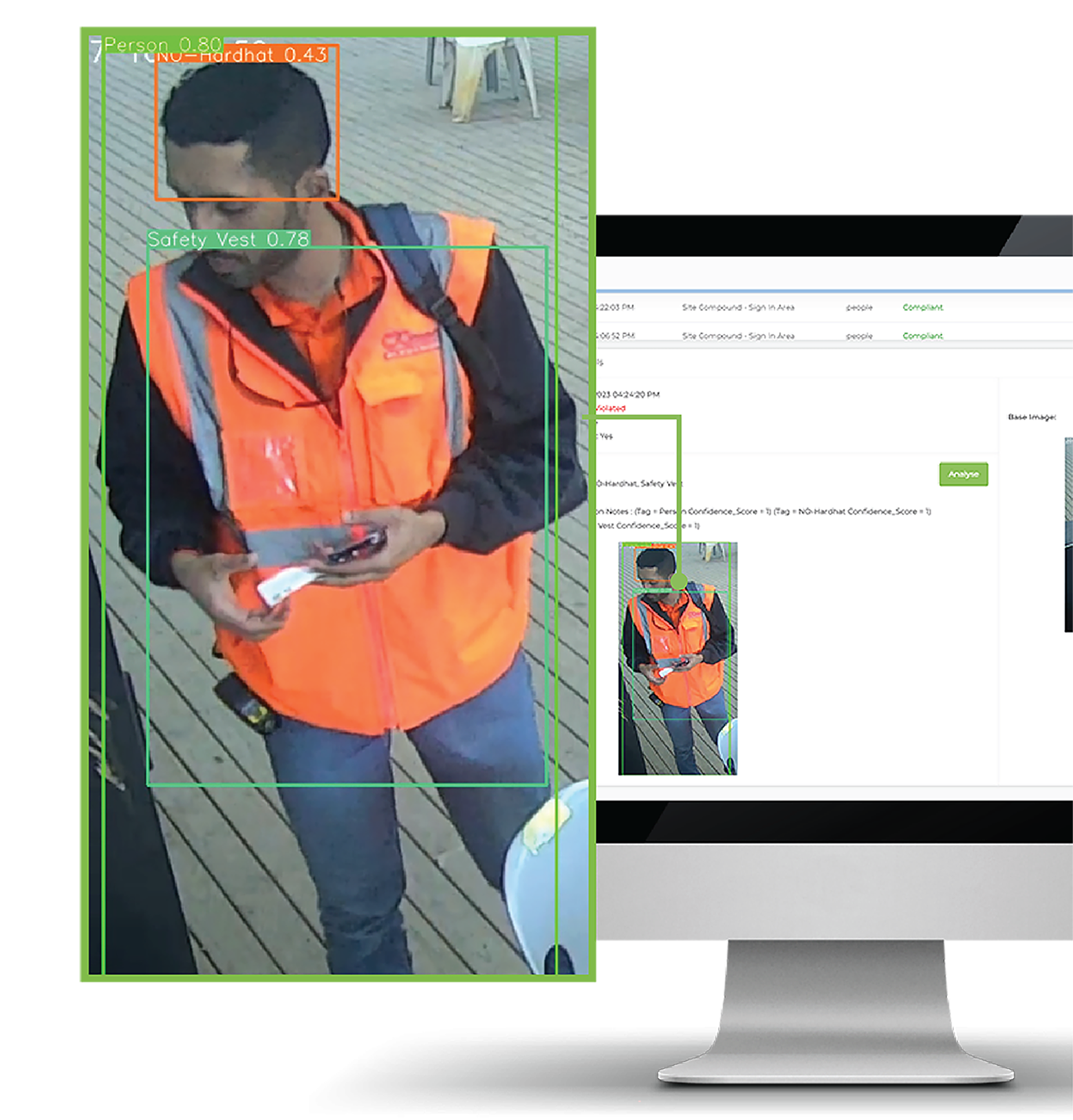

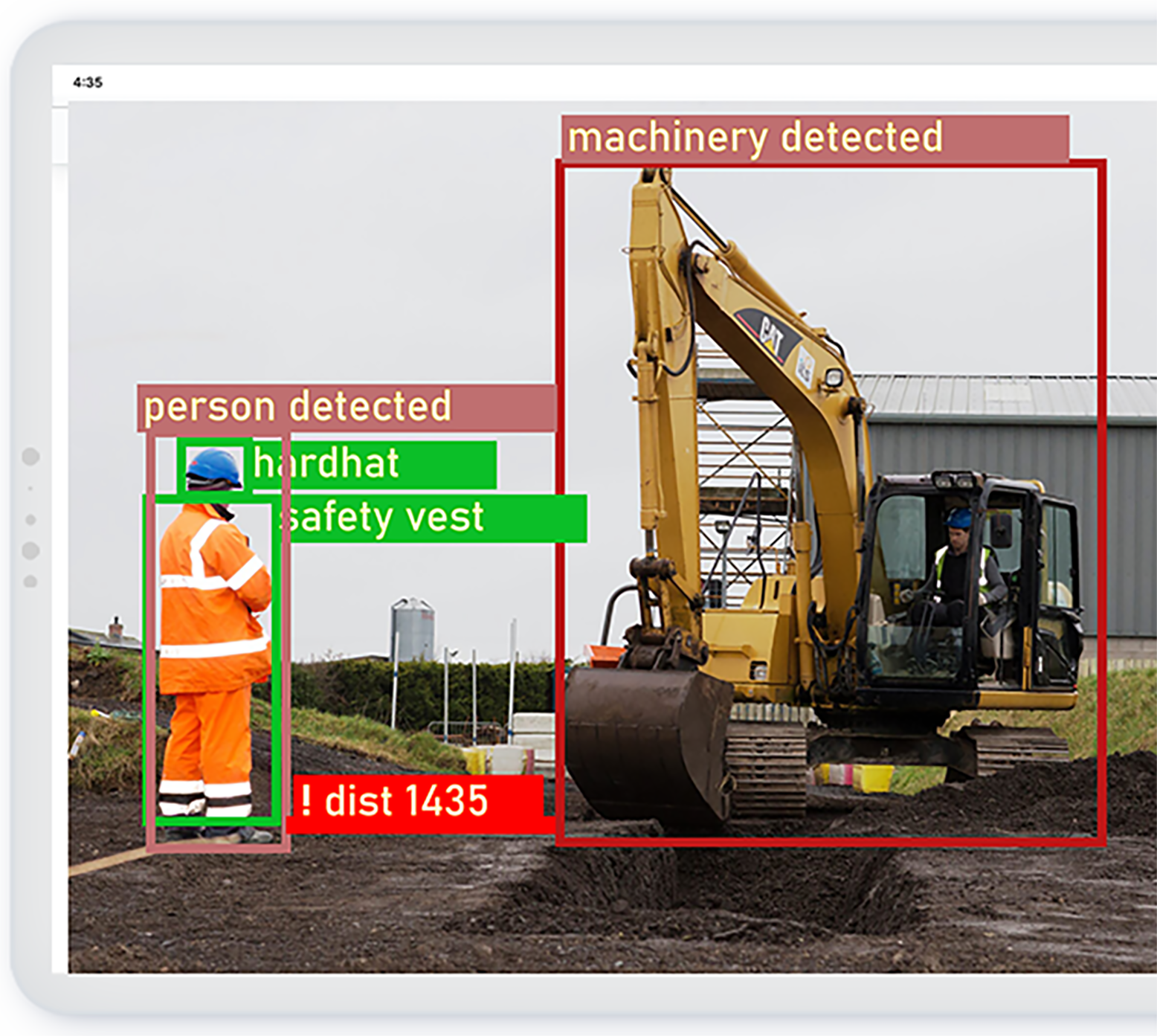

Safety PPE Detection

Identifies PPE items (hard hats, mask, safety vests, safety goggles etc) and monitors whether workers are properly wearing it while on site.

Person Down Detection

Detects when a person has fallen/tripped and triggers instant allerts.

Reports on trips and fall detection

Keeps a count record of areas with repeated trips and fall incidents and identifies hazardous areas.

RFID Tags

Utilise RFID tags which can track and identify workers who do or do not comply with PPE standards.

Rapid deployment of mobile solutions

Minedeck monitoring and detection solutions can be deployed anywhere, using mobile trailers with cameras and sensors that can be mounted onto telescopic poles, vehicles and onsite buildings.

Pedestrian vehicle/machinery accident detection

Detects when a moving person and vehicle are in a potential path of collision and advises of safer walking path practices.

Create virtual boundaries/GEO fencing

Create a virtual exclusion zone and receive real time alerts when an unauthorised worker enters the exclusion zone. Integrates with excavators and machinery, and stops machinery if the virtual boundary is crossed.

Detect potential workplace incidents

Determine safe distances between workers and machinery with exclusion zones.

Fuel and Effluent Tanks Monitoring

Monitor fuel tank levels in real time and receive alerts when tank levels reach a certain threshold.

Monitor Oil with inflow sensors to measure – dieletric, resistivity density, viscosity, temperature (to determine issues such as water ingress, cooling leaks, etc).

Effluent tanks solutions provides real-time monitoring of portable and drop toilets so that maintenance teams can optimise their cleaning schedules.

Monitor key assets

- Pipeline monitoring: Through sensors monitoring the pipeline, time spent doing this manually is significantly reduced. The monitoring can be done in real-time which can aid in reducing any potential hazards due to pipeline leakages and prevent injury or death of staff.

- Refinery monitoring: Data analytics received from IoT sensors can increase the performance of not only staff, but machinery used. Data such as pipe pressure, flow rate, among other performance parameters can be monitored remotely and in real-time, reducing time-consuming manual labour and helps to provide 24/7 monitoring of the refinery.

- Cargo shipping tracking: Keep updated in real-time of fleet and ship location through monitoring with sensor that tap into satellite to relay information back to your head office. This means you can always ‘keep an eye’ on your cargo and fleet.

Contact us

Get to know what IoT looks like in your industry or look at our cross-industry solutions. Talk to us to arrange a demo.

"*" indicates required fields