Rail Safety & Operations

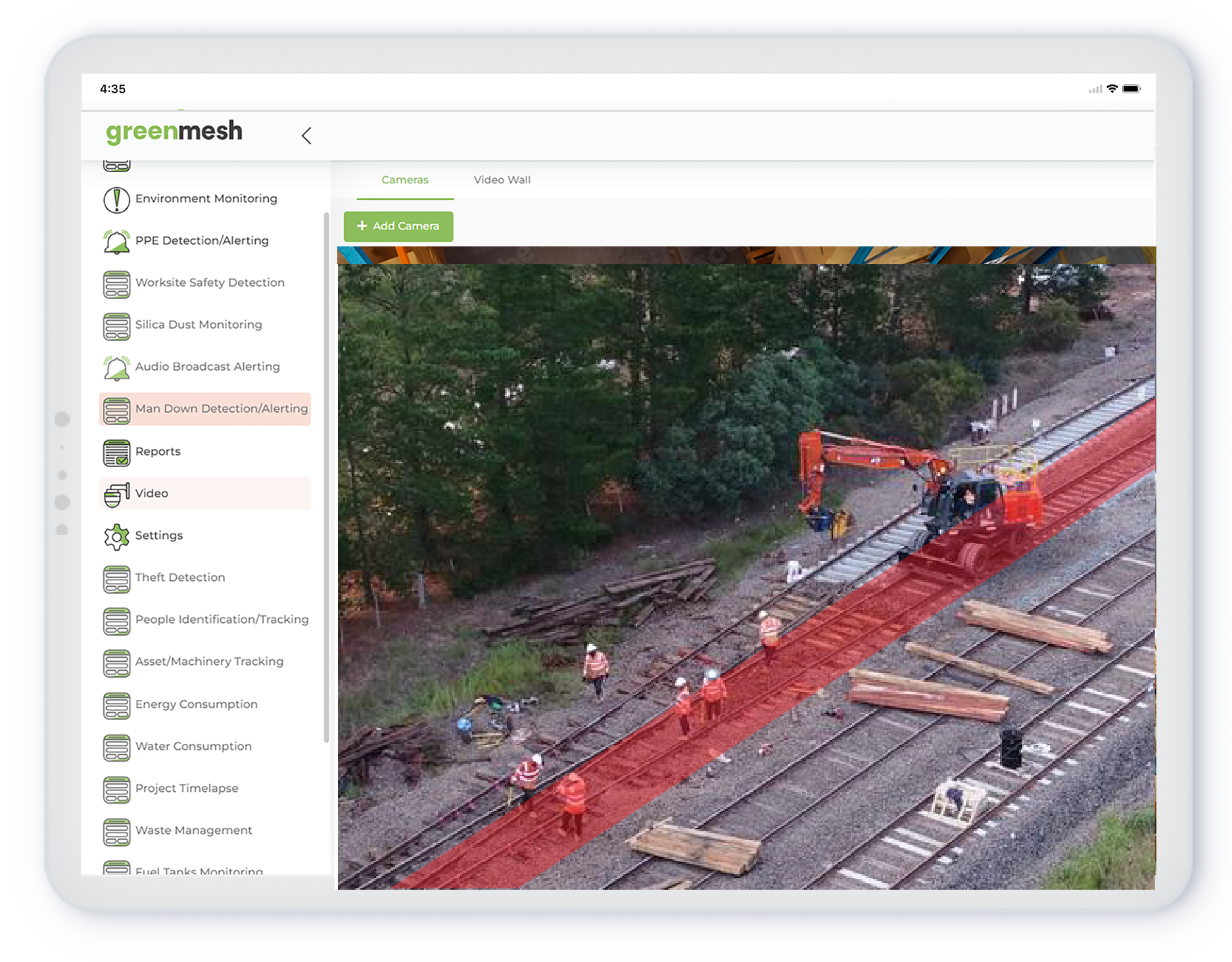

Advanced IoT Sensors and Video Analytics for Rail Safety and Operations

Greenmesh Rail Safety and Operations is a complete end-to-end IoT solution developed in Australia for use within rail environments to improve safety and security, and to provide operational efficiencies to the rail industry. Greenmesh can provide a rail operator with the following benefits:

- Level Crossing Safety utilising advanced AI and IoT sensors with early warning detection to reduce level crossing safety incidents.

- Maintenance & Operations to assist with monitoring and operational status of rolling stock and other track and rail assets.

- Security, theft & vandalism control – to detect and notify of unauthorised security threats or vandalism to existing railway locomotives or track side signs or theft of cargo associated rail assets.

- Train Locomotive Tracking & Telematics with fleet management – to provide rich information relating to locomotive operations and real-time tracking of rolling stock and associated maintenance assets.

Continuous and rapid mobile deployment solutions for anytime, anywhere, always on monitoring.

Greenmesh monitoring and detection solutions can be deployed anywhere with mobile trailers, cameras and sensors that can be mounted onto telescopic poles, vehicles and onsite depending on the railwork site’s surroundings, level crossing architecture and/or assets.

These remote solutions are self powered and can operate on a completely separate network, so they won’t impact any existing services or network.

Level Crossing Safety

Improve safety at level crossings by understanding the environment, and

improving driver awareness of the level crossing and its risk.

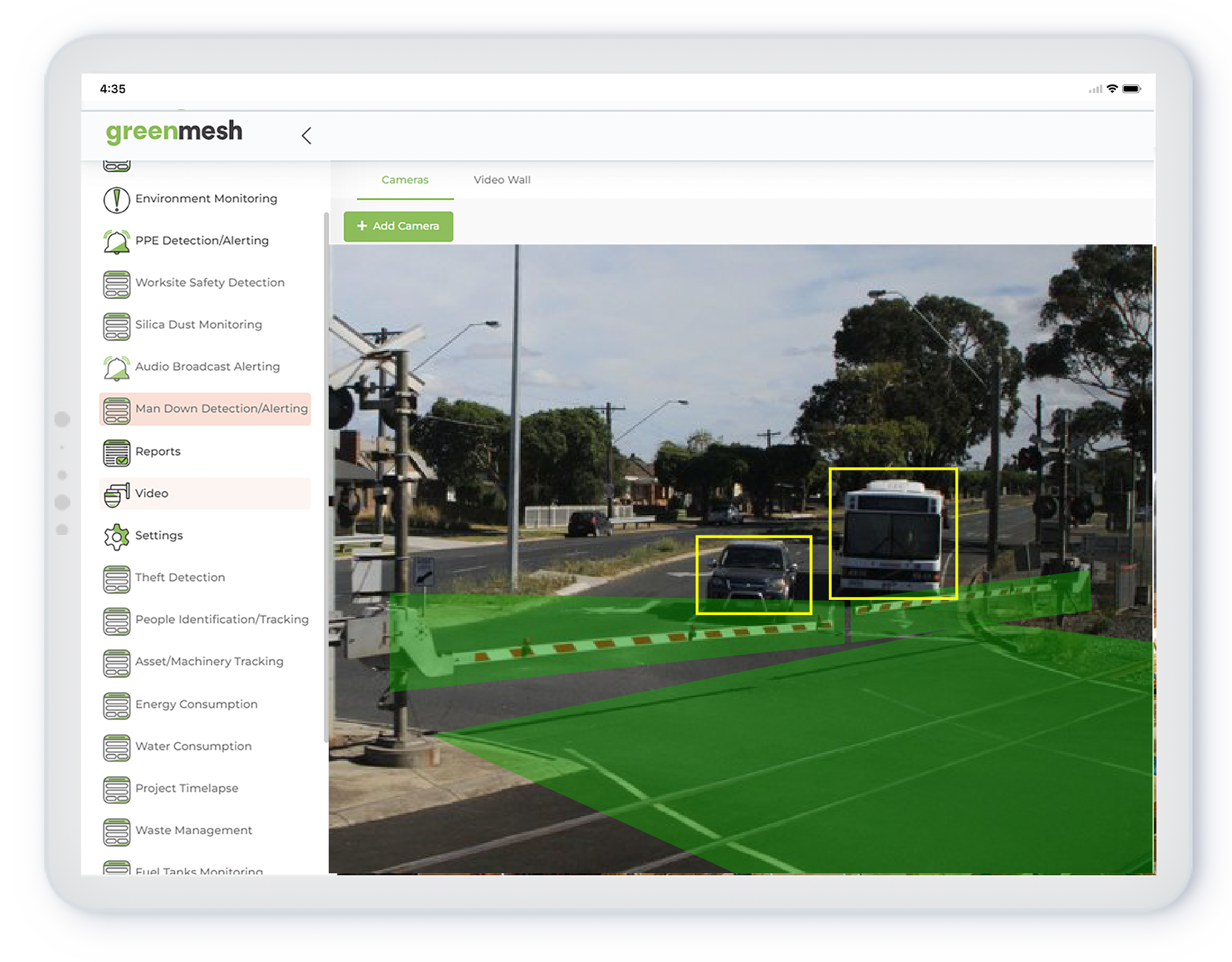

Greenmesh utilises advanced AI and machine learning, as well as purpose-built sensors to monitor rail level crossing safety.

- Detect if a vehicle doesn’t stop at a level crossing and if so, then capture vehicle details, including license plate.

- Capture footage of an approaching locomotive to verify if the locomotive forward facing lights are displaying correctly.

- Determine if there are any obstacles en route that could impact locomotive and provide early warning notification to driver and motorists.

- Utilises advanced AI architecture to monitor and predict near miss events before they happen.

Identify

- Vehicle classification and number plate recognition

- Vehicle types, colour, make, and model (ute, sedans, trucks etc)

- How many vehicles are waiting (how many per hour) and adjust wait times accordingly

- Identify vehicles of interest for maintenance rosters, schedules, compliance checks etc. ensuring teams carry out routine maintenance checks.

Detect & Alert

- Detect and alert personnel of near misses

- Detect vehicles that may be in an emergency (malfunction)

- Automate boom gates at level crossings

- Height detection: Precision grade real-time over-height detection (bridges/tunnels)

Cross level signage and outdoor digital displays

Motor vehicle drivers can receive early warning alerts of any accidents or delays. schedules, compliance checks etc.

Custom-built manufacturing solutions

Greenmesh have Australian based manufacturing facilities to custom design and build products to the users requirements (digital signage, automated boom gates which open and close based on AI recognition and identification conditions

Gain Insights

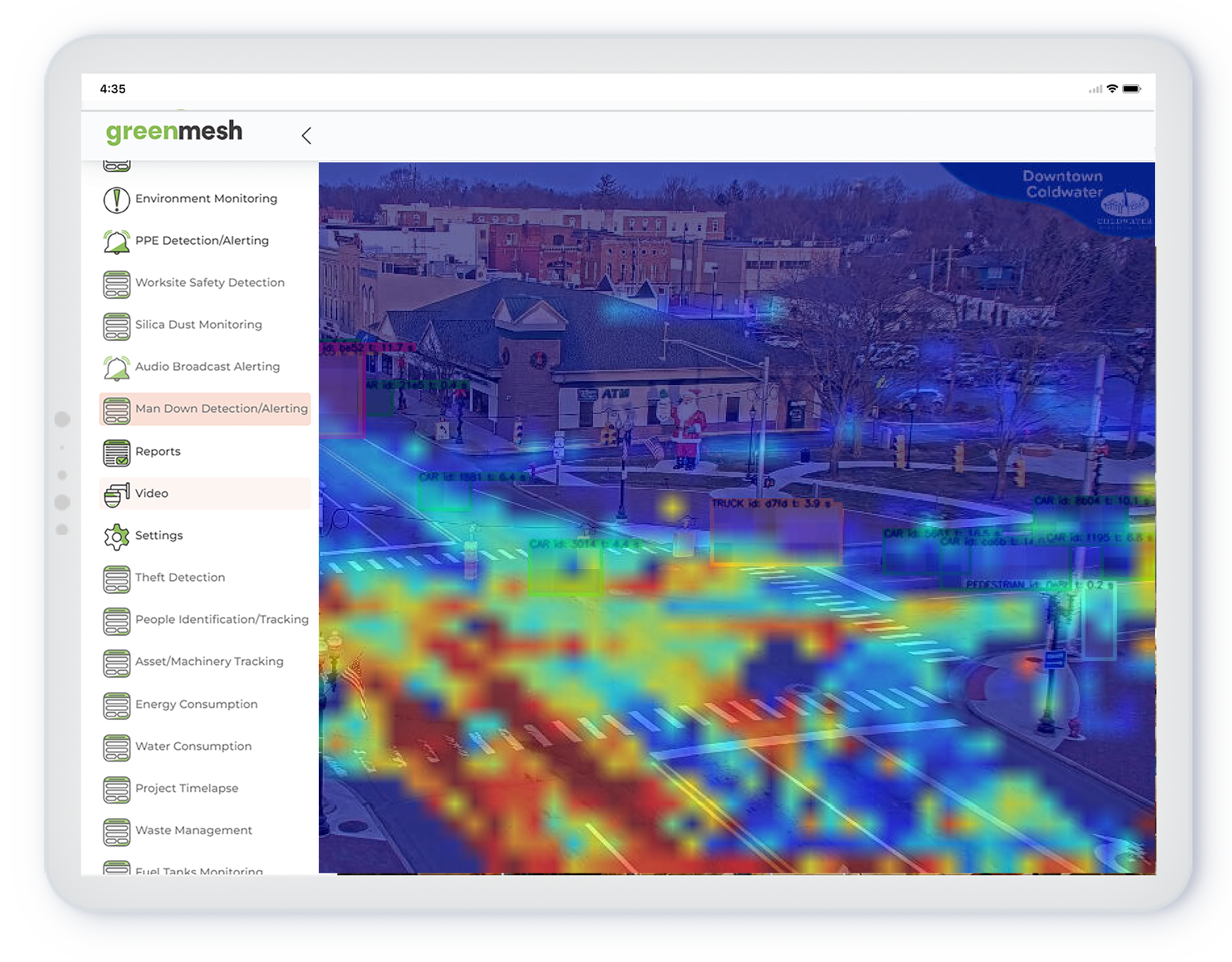

- Heat maps of traffic flow, congestion and train approach speeds

- Video footage of near misses (before and after near miss)

- Near miss predictions: Our algorithms will learn how vehicles move prior to an incident and near misses. It will then start to predict a near miss before it happens.

Maintenance and Operations

Monitor the operational status of rolling stock and other track and rail assets.

Greenmesh is also capable of aiding with maintenance and operations tasks by:

- Monitoring both sides of tracks and detecting any illegal dumping or dumping of general discarded items such as litter, waste, trolleys, furniture, etc.

- Monitoring and detecting animals on tracks or any other obstacles that could impede the safety of the locomotive

- Monitoring for any damage or defects to train and trackside train assets, tracks, overhead lines, etc.

- Providing AI analytics on vegetation growth / this would be complemented with 365mesh remote sensing satellite imagery, which provides a heat map of the exact location of where the obnoxious plants/weeds are located

- Providing real-time information relating to racks and trackside assets conditions

- Monitoring Cargo loads and helping determine load amounts (size/ volume / type of load – i.e. coal, sand, etc.) or count the quantity of logs loaded/unloaded and provide the driver with a confirmation inventory digital ticket.

Measure

- Vibration of tracks for abnormal vibration

patterns - Temperature of tracks and other trackside assets

- Power consumption

- Oil and fuel levels on trackside assets,

transformers distribution boards etc

Monitor & Detect

- Monitor for track movements (up to 20mm) utilising precision grade satellite remote sensing

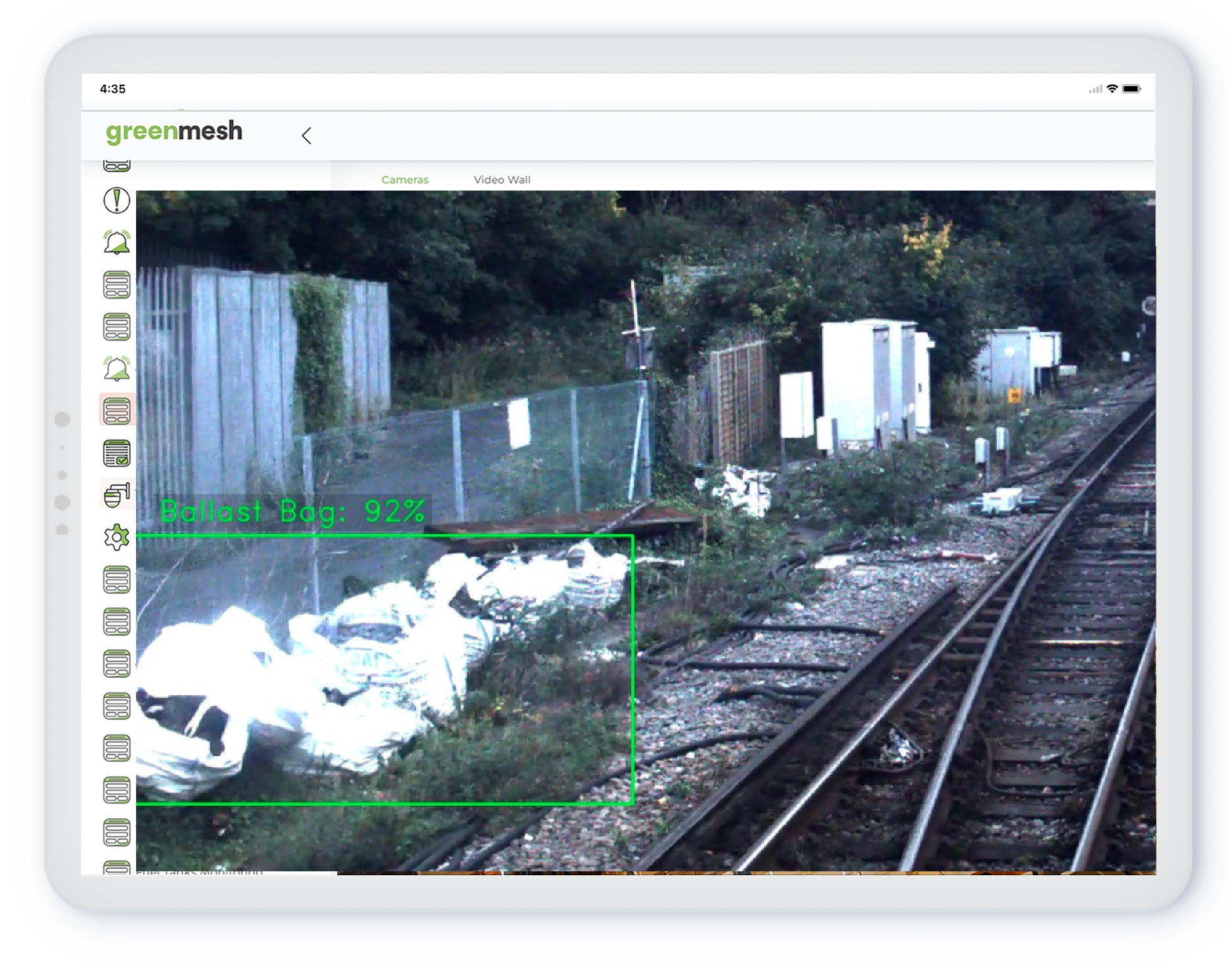

- Detect litter and dumping on the side of tracks such as trolleys, mattresses and other items that could create safety obstructions, and alert the maintenance/operational teams.

- Utilise existing cameras on carriages/locomotives with 365mesh AI to detect maintenance issues on tracks such as loose or missing bolts

- Rolling stock, wagons, locomotives (tracking and vehicle telematics)

- Digital Shields to automatically stop equipment when unsafe situation is detected using our zoning and GEO fencing capabilities

Plants and weed Detection

Unwanted plants and weeds can be accurately located using heatmaps generated with 365mesh remote sensing satellite imagery and AI analytics on vegetation growth and efficiently managed.

Illegal Dumping Detection

Monitor on both sides of tracks and detect any illegal dumping or dumping of general discarded items such as litter, waste, trolleys, furniture, etc which can become a hazardous obstacle to railway tracks.

Object and Animal Detection

Monitor and detect animals on tracks or any other obstacles that could impede the safety of the train.

Defect Detection

Monitor for any damage or defects to train and trackside train assets, tracks, overhead lines etc.

Security, Theft Detection and Vandalism Control

Detect and receive notification alerts of unauthorised security threats or vandalism to existing railway locomotives and track side signs, or theft of cargo associated rail assets.

Greenmesh Broadsecure module can provide real-time information relating to Security, Theft Detection and Vandalism Control by:

- Utilising advanced AI for security, theft detection

- Detecting vandalism of signs/assets

- Monitoring for theft of cargo or other valuable assets/materials

- Monitoring for after hours theft or activity around the trains (this feature can be activated for different times of the day and can be turned on manually or switched off as required)

- Monitoring for breaking glass or other similar noises within locomotives or surrounding trackside buildings

- Detecting intruders, vehicles or wild animals inside unauthorised areas

- Monitoring outbuildings and transformer or distribution boards / cabinets for intrusion detection and theft.

Cargo monitoring

Monitor cargo loads and assist with determining load amounts (size/ volume / type of load – ie coal, sand etc) or count logs being loaded/unloaded to provide driver with a confirmation inventory digital ticket

After hours surveillance

Monitor for after hours for theft or activities around the trains (monitoring can be activated for different times of the day and can be turned on manually or switched off as required)

Distinctive noise monitoring

Monitor noises of interest such as glass breaking, doors opening and other noises that could indicate intrusion and theft

Train Locomotive Tracking & Telematics with fleet management

Gain invaluable information relating to locomotive operations and real-time tracking of rolling stock and associated maintenance assets.

Tracking & Telematics

Vehicle Tracking

Using 4G LTE technology,

maintain real-time GPS

tracking on all locomotives and

moving vehicles. See live and

historical detailed data through

our user-friendly interface with

location updates every second.

Receive diagnostics reporting

of vehicles health and usage

remotely

Gain awareness of vehicle’s

health and usage with our real

time diagnosis reporting and

receive alerts every time a fault

code is detected.

Asset Tracking

Track other maintenance

assets to ensure real-time

location of asset.

Rollover Detection and Alerts

Provides rollover detection and

real time alerting.

Fleet management

Maintain real-time GPS

tracking on all moving vehicles.

See live and historical detailed

data through our user-friendly

interface with location updates

every second.

Collision detection and

avoidance

The installation of strategically

placed blind-spot detection

and driver monitoring

cameras onto vehicles gives

drivers real-time warnings of

hazardous collision risks.

Pre-start check and daily

reports

Fully customisable reporting

whenever a driver ignites

the engine, all sensors start

transmitting their data to the

365mesh Telematics server.

This enables you to create

detailed pre-start checks

or daily reports on vehicle

diagnostics.

Driver behaviour

Utilising advanced sensors in

driver’s cabs, detect and report

instances of harsh braking

crashes. Monitors the driver’s

behaviour such as tiredness,

falling asleep and other

behaviours that could lead to

unsafe driving conditions.

Monitor and ensure the safety of passengers in your locomotives

Locomotive Occupancy

Provide time of day room

occupancy within vehicles and

alert security if movement after

hours within the locomotive cab

is detected.

Smoke and Gas signature

detection

Measure smoke and

differentiate between smoke

and marijuana detected.

Air quality and atmospheric

contaminants monitoring

Provide time of day room

occupancy within vehicles and

alert security if movement after

hours within the locomotive cab

is detected.

Vibration Monitoring

Monitor the vibration levels

on tracks and other assets in

real time and has the ability

to set thresholds based on

compliance limits and triggers

immediate alerts.

Noise Detection and Alerts

Provide time of day room

occupancy within vehicles and

alert security if movement after

hours within the locomotive cab

is detected.

Light level Monitoring

Monitors light levels for both

vision safety and if a light is left

on after a certain time. Alerts

can be sent to personnels to

switch lights off in necessary.

Amenities Monitoring

Monitor the usage of amenities

including how frequently it is in

use and at what time, detect

leaking taps or running toilets

and schedule maintenance

accordingly.

Temperature Monitoring

Monitor temperature on tracks

and locomotives. Alerts when

tracks are over heated.

Real time video camera

surveillance with intelligent

detection

Improve the safety of the

locomotives and learn where

there may potential risks.

People Counting

Counts and keeps track of the

number of people entering,

sitting and exiting locomotives

at certain peak times.

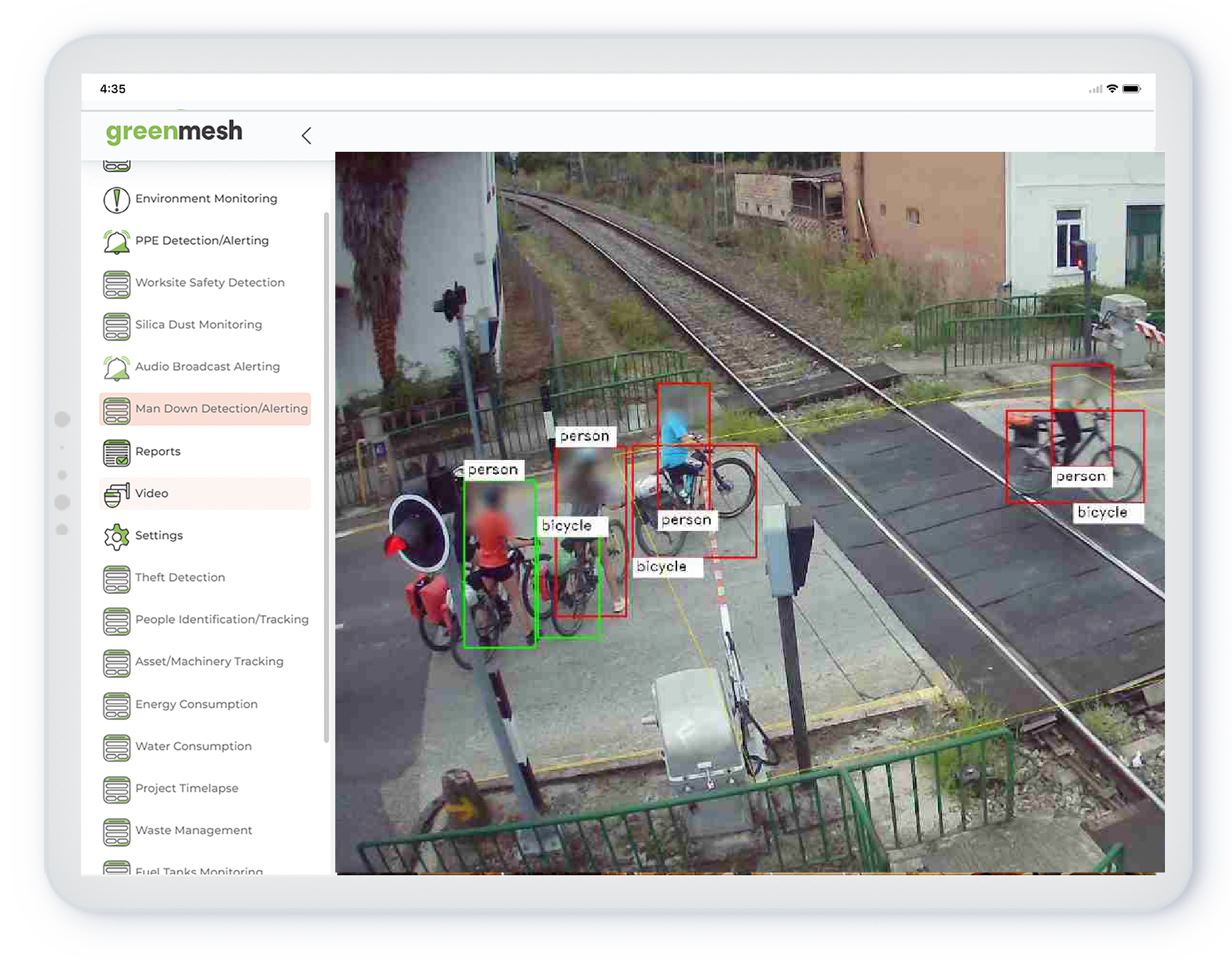

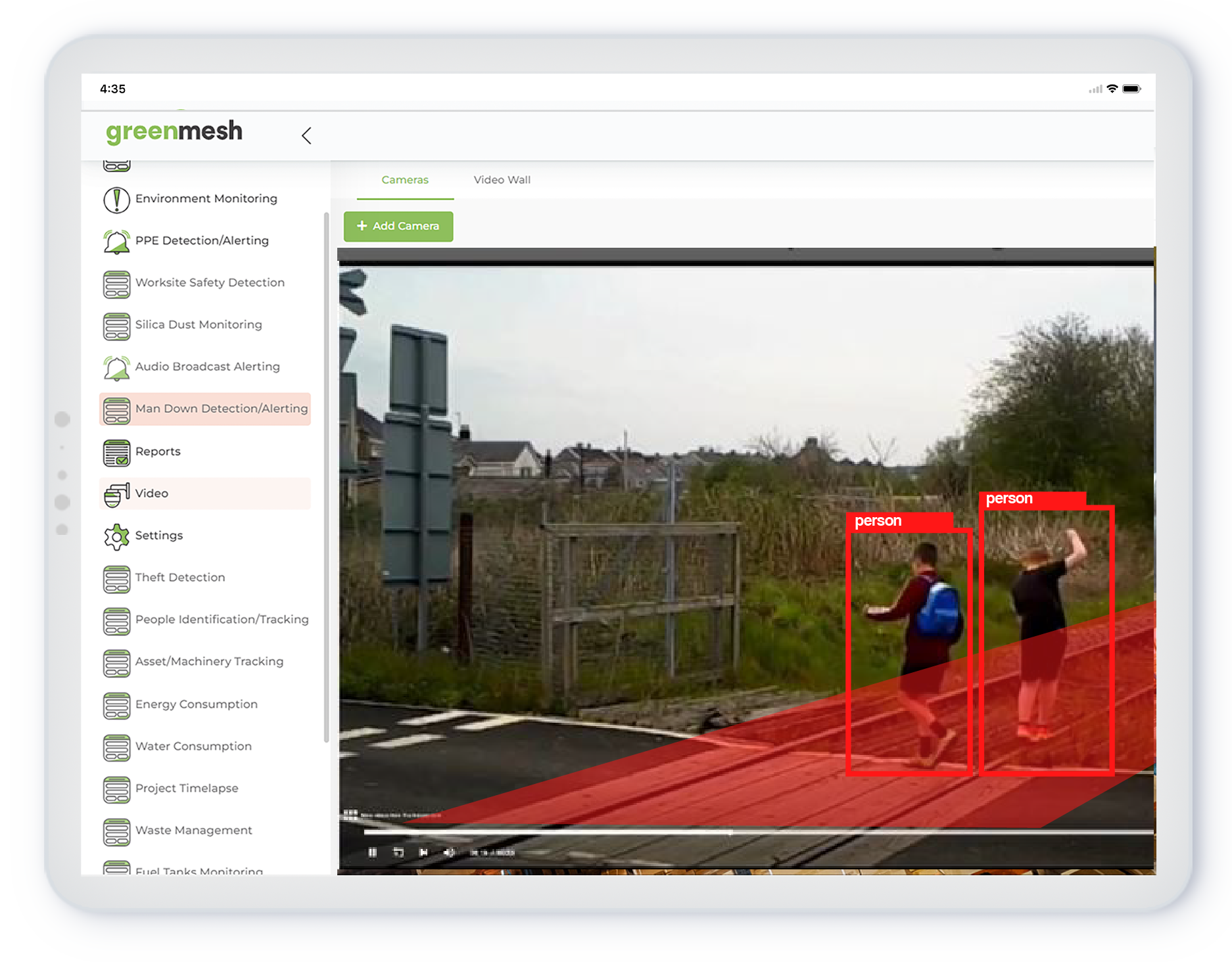

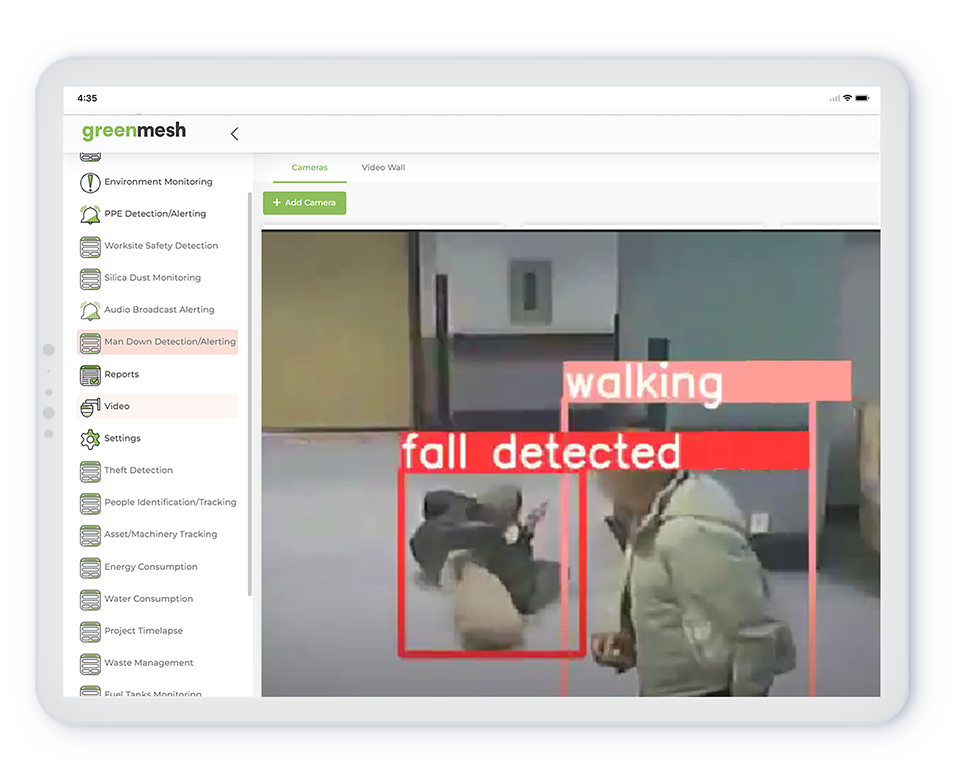

Person Down detection/alerting

Uses machine perception

and video analytics to detect

a single person or people

who have fallen or slipped,

and triggers instant alerts to

authorised personnel so they

can take immediate action.

Other Rail Operations Benefits

Rail Workplace Health & Safety

Workers in on-site railway projects often perform their work in complex and dangerous environments, which can lead to occupational accidents caused by the risks of the work area.

Our goal is to create a tailored AI prevention strategy for our users that efficiently ensures safety on work sites, prevent accidents, helps comply to industry safety standards, and automates manual checking of the correct use of PPE, which not only implies a cost, but also opens the door to human error.

Safety PPE detection

Identifies PPE items such as safety headgear, glasses, and vests. Monitors whether track workers are properly wearing PPE wear while on railway sites and restricts workers from entering job sites if all the safety wear required is not detected.

Greenmesh also utilises real time electronic RFID tags. It’s unique identification feature can identify workers who do or do not comply with PPE standards, increasing the implementation of site safety monitoring around exclusion zones and machinery safe distancing.

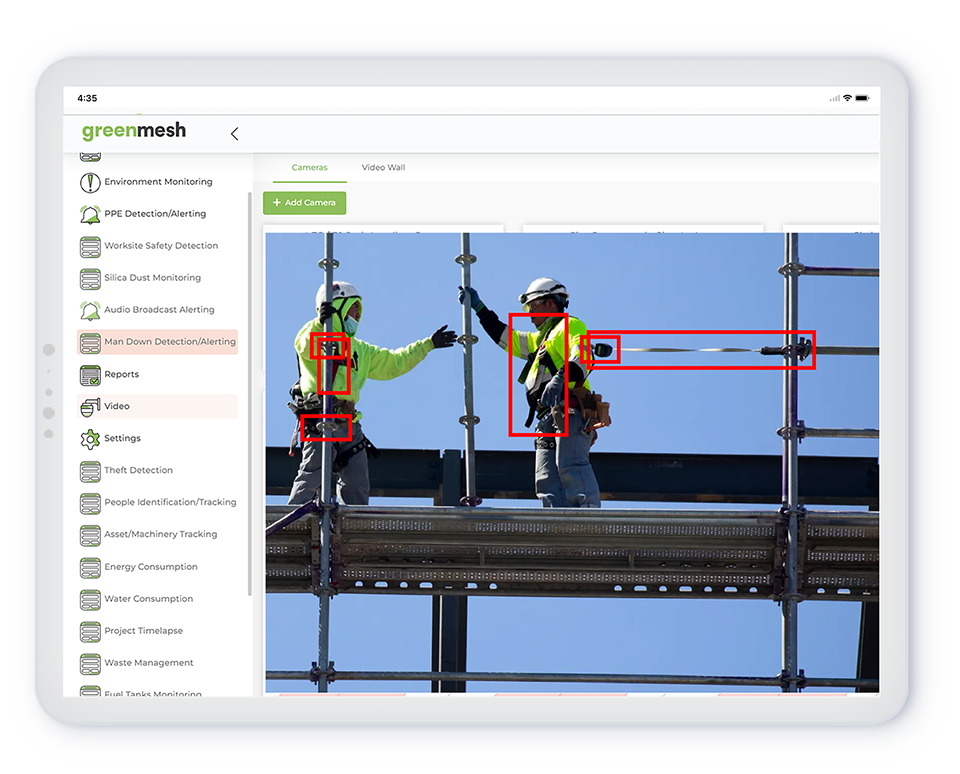

Worksite safety detection for high height risk incidents

(Harness detection and exclusion zones)

Our cameras detect if workers are working from dangerous heights without a harness, monitors and enforces exclusion zones around bridges, overhead power lines, overhead cranes, rail corridors, etc.

Person down detection & alerting

Uses machine perception and video analytics to detect a single person or people who have fallen or slipped, and triggers instant alerts to authorised personnel so they can take immediate action.

Reports on trip and fall detection

With the use of person down alerting, Greenmesh keeps a count record of areas with repeated trips and fall incidents, such as certain track areas, giving users an accurate record of accident occurrences.

Detect potential workplace

incidents between workers

and moving vehicles

Determine safe distances between workers and moving machinery/ equipment with exclusion zones. This involves the installation of strategically placed blind spot detection and driver monitoring cameras onto vehicles to give drivers real time warnings of hazardous collision risks such as other objects or people who are close by.

Create virtual boundaries/GEO

fencing and receive boundary

intrusion alerts.

Our algorithms in the cameras deployed allows users to create a virtual safety and exclusion zone radius around potentially dangerous tracks such as faulty tracks and machinery, monitor these areas and receive real time alerts when an unauthorised worker or other vehicles enters the exclusion zone, indicating that they are too close and may be in the way of danger.

Digital shield to automatically stop equipment when unsafe situation is

detected

Utilising our boundaries and GEO fencing capabilities, users can set up virtual fences around dangerous machinery and which will automatically switch off machines if a person or object is detected in the boundary, preventing machinery accidents.

Interested in learning more?

Reach out to us, and send us a message, by hitting the Contact Us button below, and filling out your details.